If you’re noticing strange noises or leaks coming from your hydraulic cylinder, it might be time for a repair.

Hydraulic cylinders are an essential part of many machines and can be found in a variety of industries, from construction to manufacturing. While they are built to last, over time they can start to wear down and require repairs.

There are a few things you can do to troubleshoot your hydraulic cylinder and see if a repair is necessary.

This article will give you an overview of what to look for and how to go about repairing your hydraulic cylinder.

By following these tips, you can keep your machine running smoothly and avoid costly downtime.

Table of Contents

What is a Hydraulic Cylinder?

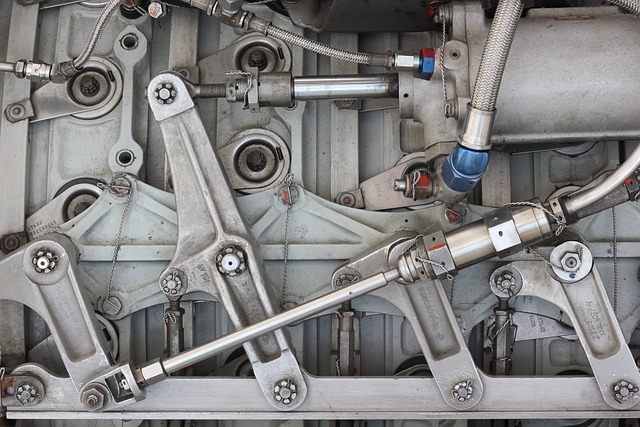

A hydraulic cylinder is a device that uses fluid pressure to generate linear force.

It consists of a cylinder barrel, in which a piston moves back and forth. The piston is connected to a rod, which extends out of the cylinder on one side. When fluid pressure is applied to the piston, it creates a force that drives the rod outward.

Hydraulic cylinders are used in a variety of applications, including construction equipment, automotive components, and manufacturing machinery. They are often preferred over other types of cylinders because they can generate large amounts of force with relatively little effort.

In addition, hydraulic cylinders can be used to create linear motion in either direction, making them versatile and easy to use.

Signs that You Need a Repair

As a business owner, I rely on my hydraulic cylinders to keep my operation running smoothly. That’s why I always pay close attention to how they’re performing.

Over time, they can start to show signs of wear and tear. If I notice any of these signs, then I know it’s time to take them in for repair.

One of the most common signs that a hydraulic cylinder needs repair is a loss of power. If the cylinder isn’t able to generate enough force, then it won’t be able to perform its task properly.

Another sign is leakage. If hydraulic fluid is leaking from the cylinder, then it’s not going to be able to hold pressure.

Finally, if the cylinder is making strange noises, then that’s another sign that something is wrong and it needs to be looked at by a professional.

If you notice any of these signs, then don’t hesitate to take your hydraulic cylinder in for repair. A professional will be able to diagnose the problem and get your cylinder back up and running in no time.

Tips for Troubleshooting Your Hydraulic Cylinder

If your hydraulic cylinder isn’t working properly, there are a few things you can do to troubleshoot the issue.

First, check the level of fluid in the reservoir. If the fluid is low, add more until it reaches the full line. Next, check the hoses for any leaks or cracks. If you find any damage, replace the hose.

Finally, check the connecting rods and piston for any damage. If you see any cracks or gouges, you’ll need to replace the cylinder.

By following these steps, you should be able to identify and fix any problems with your hydraulic cylinder.

Conclusion: Keep Your Machine Running Smoothly with Regular Maintenance

Regular maintenance is the key to keeping your machine running smoothly. By checking and lubricating the moving parts on a regular basis, you can prevent costly repairs down the road.

In addition, regular maintenance can help to extend the life of your machine. By taking the time to care for your machine, you can ensure that it will provide years of reliable service.